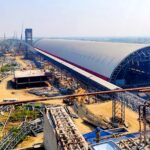

In the bustling world of seaport operations, coal storage presents a unique set of challenges. As a vital commodity in energy production, coal must be stored efficiently and safely to meet industry demands. However, traditional storage methods often fall short in addressing environmental concerns, leading to pollution and contamination risks. Enter pollution control covered sheds, powered by Metalkarma’s spaceframes technologies, offering a groundbreaking solution that balances industry needs with environmental responsibility. Let’s delve into how these innovative structures are reshaping seaport coal storage operations.

1. Environmental Protection at the Seaport:

Seaport coal storage facilities are susceptible to environmental pollution, with open-air stockpiles contributing to dust emissions and contamination risks. Pollution control covered sheds provide a protective barrier that minimizes the release of pollutants into the air and water, safeguarding surrounding ecosystems and communities from harm. Metalkarma’s spaceframes technologies ensure durable and resilient structures that effectively mitigate environmental impact.

2. Efficient Storage Solutions:

The expansive interior space of pollution control covered sheds allows for efficient storage of coal at seaport facilities. By optimizing storage capacity and organization, these structures enhance operational efficiency and streamline material handling processes. Metalkarma’s spaceframes enable the construction of large-span sheds without the need for internal support columns, maximizing usable space and storage flexibility.

3. Compliance with Environmental Regulations:

Investing in pollution control covered sheds demonstrates a commitment to regulatory compliance and environmental responsibility. By mitigating pollution and contamination risks associated with open-air stockpiles, seaport operators can ensure compliance with stringent environmental regulations and sustainability standards. Metalkarma’s spaceframes technologies support industry efforts to uphold environmental stewardship and meet regulatory requirements.

4. Protection of Coal Quality:

Covered sheds create a controlled environment that preserves the quality and integrity of stored coal at seaport facilities. By shielding coal from exposure to moisture, sunlight, and airborne pollutants, these structures maintain the calorific value and chemical composition of coal, ensuring its suitability for energy production. Metalkarma’s spaceframes technologies provide durable and weather-resistant sheds that protect coal from degradation and contamination.

5. Sustainable Seaport Operations:

Pollution control covered sheds contribute to sustainable seaport operations by minimizing environmental impact and promoting responsible resource management. By reducing pollution and contamination risks, these structures support efforts to create cleaner, healthier port environments and reduce the ecological footprint of coal storage operations. Metalkarma’s spaceframes technologies align with industry goals of sustainability and environmental stewardship, driving progress towards a greener future.

Conclusion:

Seaport coal storage pollution control covered sheds, powered by Metalkarma’s spaceframes technologies, represent a significant advancement in balancing industry needs with environmental responsibility. By providing environmental protection, efficient storage solutions, regulatory compliance, protection of coal quality, and sustainable operations, these innovative structures are reshaping the landscape of seaport coal storage operations. As seaports strive to meet the dual objectives of industry efficiency and environmental sustainability, pollution control covered sheds offer a compelling solution that embodies the principles of responsible resource management and ecological stewardship.