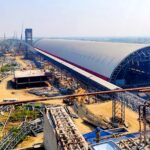

In the dynamic landscape of dry bulk storage, innovation is key to meeting evolving industry demands and overcoming emerging challenges. As we look to the future, several trends are poised to shape the dry bulk storage industry, presenting both challenges and opportunities for stakeholders. In this blog, we’ll explore how Metalkarma’s spaceframe technologies are positioned to address these trends and drive innovation in dry bulk storage.

1. Automation and Digitalization:

Future trends in dry bulk storage are expected to be heavily influenced by automation and digitalization. Automated storage systems, powered by advanced robotics and AI, will revolutionize material handling processes, optimizing efficiency and reducing labor costs. Metalkarma’s spaceframe technologies are compatible with automation systems, offering flexible and scalable solutions that enable seamless integration of automated storage technologies.

2. Sustainability and Environmental Responsibility:

Environmental sustainability is increasingly becoming a priority in the dry bulk storage industry. Companies are seeking eco-friendly solutions to reduce their carbon footprint and minimize environmental impact. Metalkarma’s spaceframe technologies support sustainability initiatives by offering lightweight, durable structures that can be constructed using recyclable materials. Additionally, these structures can be equipped with energy-efficient features such as solar panels and rainwater harvesting systems, further reducing environmental impact.

3. Modular and Scalable Solutions:

The trend towards modular and scalable storage solutions is driven by the need for flexibility and adaptability in the face of changing market conditions. Metalkarma’s spaceframe technologies excel in this regard, offering customizable solutions that can be easily expanded or reconfigured to meet evolving storage requirements. Whether it’s accommodating fluctuations in storage capacity or integrating new technologies, Metalkarma’s spaceframe structures provide the versatility needed to future-proof dry bulk storage facilities.

4. Advanced Monitoring and Analytics:

Real-time monitoring and analytics are becoming increasingly important for optimizing dry bulk storage operations. By leveraging IoT sensors and data analytics platforms, companies can gain valuable insights into storage conditions, inventory levels, and equipment performance. Metalkarma’s spaceframe technologies support the integration of monitoring and analytics systems, providing a robust framework for data-driven decision-making and predictive maintenance strategies.

5. Enhanced Safety and Security:

Ensuring the safety and security of dry bulk storage facilities is paramount for protecting personnel, equipment, and valuable assets. Metalkarma’s spaceframe structures are engineered to meet stringent safety standards, offering robust construction and durability that withstands harsh environmental conditions and external threats. Additionally, these structures can be equipped with advanced security features such as access control systems and surveillance cameras, further enhancing safety and security measures.

Conclusion:

As the dry bulk storage industry continues to evolve, embracing innovation and leveraging advanced technologies will be critical for staying ahead of the curve. Metalkarma’s spaceframe technologies are at the forefront of driving innovation in dry bulk storage, offering versatile, sustainable, and future-ready solutions that address emerging trends and challenges. By partnering with Metalkarma, companies can unlock new opportunities and position themselves for success in the dynamic world of dry bulk storage.