METALKARMA ENGINEERING TECHNOLOGIES PVT LTD.

Only Indian Spaceframe Company to have inhouse forging space frame manufacturing, designing and execution.

Corporate Office: #6, Vinir Towers, 100ft BTM main Road, 1st ph, 1st Stage, BTM Layout,

BANGALORE 560 068, India.

NO.14, KIADB ATTIBELE INDUSTRIAL AREA,

BANGALORE 562 107.

Our Speciality

Services

Our competent and dedicated team of professional engineers turned technocrats of the space frame industry create customized software for design and related structural analysis.

MET philosophy of continuous improvement of its technology and dedication to render value added products and services to its customers, after many years of continuing in house research

Besides, full space frame assembly of MET, including all structural elements such as pipe, cone, bolt, sleeve, spherical steel ball (node), pipe/cone welding are subjected to tension

Metalkarma Working

Process

Our Expertise

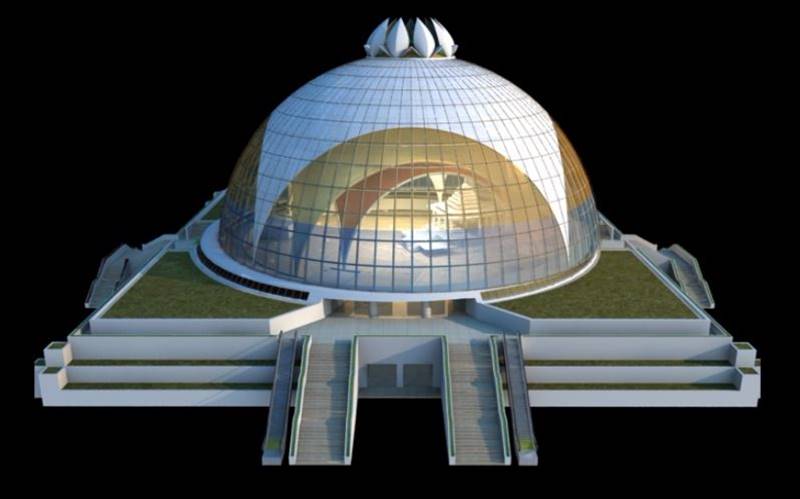

MET Space frame is prefabricated three dimensional spaceframe systemin the true sense of the word . There will not be a need for any additional work at the site including the last layer of paint. It is being packed in a special way to protect the powder coated members from scratches ,when loading/unloading with cranes or forklifts

Installation

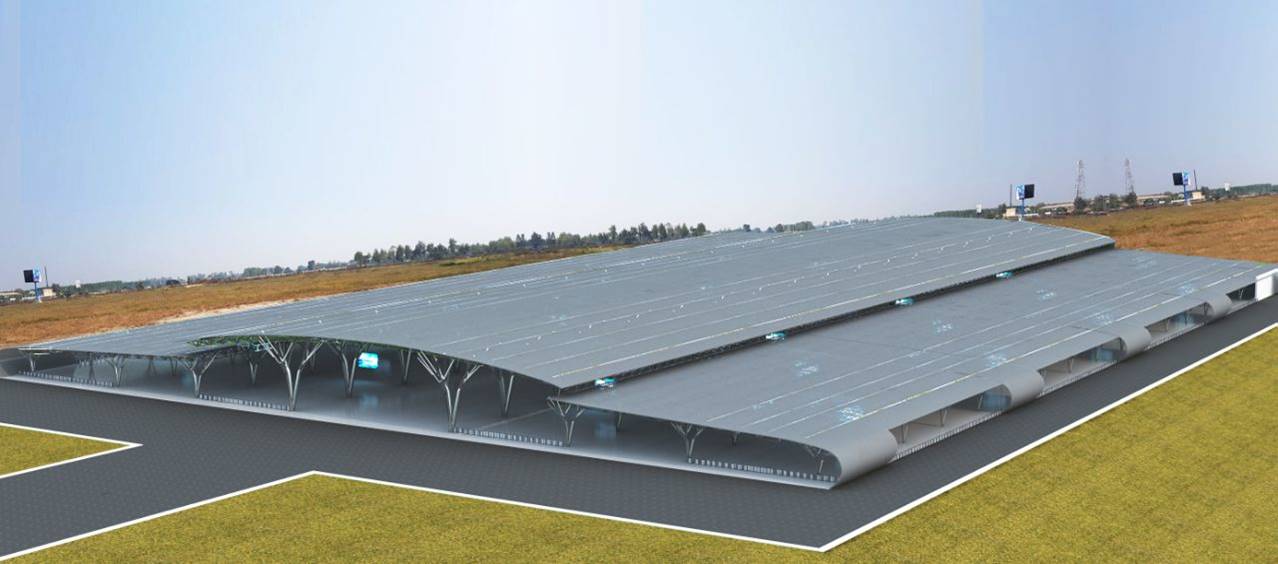

These are carried out by a network of Qualified and Certified Builders working hand-in-hand with MET to ensure satisfactory completion of works. Erection is generally categorized into three

methods or combination thereof depending upon the actual site conditions namely: In-situ assembly from either full height mobile or fixed scaffolds.

Full assembly on ground and lift into position using appropriate sized crane. Partial assembly on ground, lift into position by crane and complete assembly by mobile scaffolds.

The completed space frame will undergo full and comprehensive

final inspection before hand-over to clients.

Contact us for any kind of help at any time

Corporate Office: #6, Vinir Towers, 100ft BTM main Road, 1st ph, 1st Stage, BTM Layout,

BANGALORE 560 068, India.

Factory Address:

Unit 1 : NO.14,KIADB ATTIBELE INDUSTRIAL AREA,

BANGALORE 562 107.

Tel:+91 80 29601551

info@metalkarma.in

sales2@metalkarma.in

Mobile: +91-9632219455

Email:

design@metalkarma.in/

marketing@metalkarma.in

© 2025, Metalkarma All Right Reserved.

Saudi Arabia Address:

MET STEEL INDUSTRIES L.L.C

Road no.114, Opp traffic Police office, Jubail Industrial City-31961,Kingdom of Saudi Arabia

C.R. 7050527170

Contact No:

+966 55 142 3997

Email:

maaz@metalkarma.in