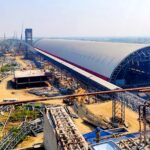

In the fast-paced world of aerospace manufacturing, efficiency and precision are paramount. The Final Assembly Line (FAL) stands as the nexus of aeroplane production, where every component must seamlessly come together to create the marvels of modern aviation. At the heart of this intricate dance lies Metalkarma’s spaceframe technologies, redefining the role of covered sheds in optimizing aeroplane assembly. Let’s explore how these cutting-edge solutions are transforming FAL operations and driving aerospace excellence.

1. Shielding Aerospace Marvels with Precision:

Metalkarma’s spaceframe technologies provide a shield of precision around every aerospace component during assembly. These innovative structures offer unparalleled protection against the elements, shielding delicate components from rain, wind, and harsh sunlight. By maintaining optimal environmental conditions, covered sheds ensure the integrity and quality of each aircraft, setting the stage for flawless flight.

2. Precision-Crafted Environments for Meticulous Work:

In the world of aerospace manufacturing, precision is everything. Metalkarma’s spaceframe-covered sheds create controlled environments that are tailor-made for meticulous work. Shielded from external disruptions like temperature fluctuations and inclement weather, assembly personnel can focus on their tasks with laser-like precision. This controlled environment minimizes errors and rework, elevating the quality and efficiency of aeroplane assembly.

3. Streamlining Workflow Efficiency with Seamless Segregation:

Covered sheds by Metalkarma are meticulously designed to streamline the aeroplane assembly process. Each stage of production, from fuselage assembly to wing installation and interior fit-out, has its dedicated space within these versatile structures. This seamless segregation optimizes workflow efficiency, eliminating congestion and bottlenecks. Assembly teams can progress seamlessly from one task to the next, maximizing throughput and meeting production targets with ease.

4. Safety and Security at the Forefront:

Safety is non-negotiable in aerospace manufacturing, and Metalkarma’s covered sheds prioritize the well-being of assembly personnel. Shielded from external hazards, workers operate in a secure environment that is free from unnecessary risks. Controlled access and enhanced security measures ensure the safety and integrity of valuable aerospace assets, protecting them from theft, tampering, or damage.

5. Flexibility and Scalability for Future-Ready FALs:

Metalkarma’s spaceframe technologies offer unparalleled flexibility and scalability, ensuring that FALs remain future-ready in a rapidly evolving industry landscape. As production demands fluctuate or new aircraft models are introduced, covered sheds can be effortlessly reconfigured or expanded to accommodate changing requirements. This adaptability ensures that FALs can quickly pivot to meet market demands, maintaining competitiveness and agility in the aerospace sector.

Conclusion:

Metalkarma’s spaceframe technologies are revolutionizing aeroplane assembly, elevating Final Assembly Lines to new heights of efficiency, precision, and quality. By providing unmatched protection, precision-crafted environments, streamlined workflow efficiency, safety and security, and flexibility and scalability, covered sheds by Metalkarma are driving innovation and excellence in aerospace manufacturing. As the aerospace industry continues to soar to new horizons, Metalkarma remains at the forefront, powering the future of aeroplane assembly with its transformative spaceframe technologies.