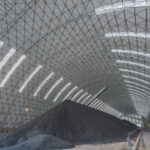

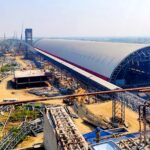

In the competitive landscape of large-scale manufacturing, optimizing operational costs while maintaining quality and efficiency is paramount. Industrial coverage sheds provided by Metalkarma Spaceframe Technologies offer cost-effective solutions that directly impact the bottom line of large manufacturers. In this blog, we’ll explore how these innovative structures drive value and contribute to the financial success of large manufacturing operations.

1. Reduced Construction Costs:

Metalkarma Spaceframe Technologies’ industrial coverage sheds are engineered with efficiency in mind. Their modular design and streamlined construction processes result in reduced labor and material costs compared to traditional building methods. Large manufacturers can achieve significant savings on construction expenses, allowing them to allocate resources to other critical areas of their operations.

2. Minimal Maintenance Requirements:

Maintaining traditional industrial structures can be a significant ongoing expense for large manufacturers. However, Metalkarma’s spaceframe technology offers durable, low-maintenance solutions. The corrosion-resistant materials and robust construction of these sheds minimize the need for frequent repairs and upkeep, reducing long-term maintenance costs and ensuring a higher return on investment over time.

3. Energy Efficiency:

Energy costs represent a significant portion of operating expenses for large manufacturing facilities. Metalkarma’s industrial coverage sheds can be equipped with energy-efficient features such as insulation, natural lighting solutions, and ventilation systems. By optimizing energy usage and reducing reliance on artificial lighting and climate control systems, manufacturers can realize substantial savings on utility bills, contributing to improved cost-effectiveness.

4. Scalability and Flexibility:

Metalkarma’s spaceframe technology offers scalability and flexibility, allowing large manufacturers to adapt their facilities to changing operational needs without incurring significant additional costs. Whether expanding production capacity, reconfiguring storage areas, or integrating new equipment, these sheds can be easily modified and expanded to accommodate evolving requirements, minimizing the need for costly facility renovations or expansions.

5. Enhanced Operational Efficiency:

By providing sheltered workspace and storage areas, Metalkarma’s industrial coverage sheds optimize operational efficiency for large manufacturers. Protected from the elements, workers and equipment can operate more consistently and safely, reducing downtime due to weather-related interruptions or equipment damage. This increased productivity directly translates into cost savings and improved profitability for the manufacturing facility.

6. Faster Deployment and Return on Investment:

Metalkarma’s industrial coverage sheds are designed for rapid deployment, allowing large manufacturers to start realizing cost savings and operational benefits sooner. The shorter construction timeline means a quicker return on investment, enabling manufacturers to recoup their initial expenditure more rapidly and begin enjoying the long-term financial benefits of their investment.

Conclusion:

Metalkarma Spaceframe Technologies’ industrial coverage sheds offer a range of cost-effective solutions that directly impact the bottom line for large manufacturers. From reducing construction and maintenance costs to optimizing energy efficiency and enhancing operational efficiency, these innovative structures drive value and contribute to the financial success of manufacturing operations. By investing in Metalkarma’s spaceframe technology, large manufacturers can achieve significant cost savings, improve profitability, and position themselves for long-term success in the competitive manufacturing landscape.