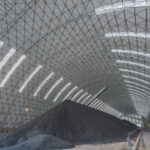

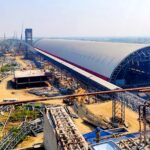

In the realm of dry bulk storage, efficiency and cost savings are paramount goals for businesses seeking to streamline operations and maximize profitability. Metalkarma’s spaceframe covered sheds offer an innovative solution to achieve these objectives by providing versatile, durable, and cost-effective storage structures. In this blog, we’ll explore strategies for optimizing dry bulk storage facilities using Metalkarma’s spaceframe covered sheds, and how they contribute to increased efficiency and savings.

1. Flexible Layout Design:

Metalkarma’s spaceframe covered sheds offer customizable designs that can be tailored to suit the specific needs and requirements of dry bulk storage facilities. By optimizing the layout design, businesses can maximize space utilization, minimize material handling distances, and improve workflow efficiency. Whether it’s configuring multiple storage bays, integrating conveyor systems, or incorporating loading docks, the flexibility of Metalkarma’s covered sheds allows for seamless adaptation to operational needs, leading to increased efficiency and cost savings.

2. Modular Construction and Scalability:

One of the key advantages of Metalkarma’s spaceframe covered sheds is their modular construction, which allows for rapid deployment and easy scalability. Businesses can start with a basic storage structure and gradually expand or modify it as storage needs evolve. This scalability ensures that businesses can adapt to changing market demands without the need for extensive construction or costly renovations. By investing in a scalable storage solution, businesses can optimize their capital expenditure and achieve long-term cost savings.

3. Enhanced Durability and Reliability:

Metalkarma’s spaceframe covered sheds are engineered for durability and reliability, providing a robust storage solution that withstands harsh environmental conditions and heavy-duty usage. The high-quality materials and construction techniques ensure long-term performance and minimal maintenance requirements, reducing downtime and operational costs. With Metalkarma’s covered sheds, businesses can rely on a dependable storage infrastructure that delivers consistent performance and peace of mind.

4. Energy-Efficient Solutions:

Incorporating energy-efficient features into dry bulk storage facilities can lead to significant cost savings over time. Metalkarma’s spaceframe covered sheds can be equipped with insulation, ventilation systems, and natural lighting solutions to optimize energy usage and reduce utility costs. By minimizing heat loss, controlling humidity levels, and harnessing natural light, businesses can lower their energy consumption and operational expenses, contributing to long-term cost savings and environmental sustainability.

5. Streamlined Maintenance and Operations:

Metalkarma’s spaceframe covered sheds are designed for easy maintenance and streamlined operations, minimizing downtime and maximizing productivity. With features such as corrosion-resistant materials, smooth surfaces, and modular components, maintenance tasks are simplified and completed more efficiently. Additionally, the durability and reliability of Metalkarma’s covered sheds ensure uninterrupted operations, reducing the risk of costly disruptions and downtime.

Conclusion:

Optimizing dry bulk storage facilities is essential for businesses seeking to enhance efficiency and achieve cost savings. Metalkarma’s spaceframe covered sheds offer a versatile, durable, and cost-effective solution that enables businesses to maximize space utilization, scalability, durability, energy efficiency, and streamlined operations. By leveraging the advantages of Metalkarma’s covered sheds, businesses can optimize their dry bulk storage operations, reduce operational costs, and achieve long-term success in a competitive market landscape.