Large-scale manufacturing facilities require robust and versatile structures to protect their operations and assets. Choosing the right industrial coverage shed is crucial for ensuring efficiency, safety, and long-term success. Metalkarma’s spaceframe coverage sheds offer innovative solutions tailored to the unique needs of large-scale manufacturing. In this blog, we’ll explore the key factors to consider when selecting the ideal industrial coverage shed and how Metalkarma’s spaceframe technology aligns with these requirements.

1. Durability and Structural Integrity:

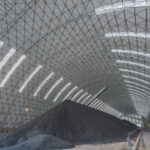

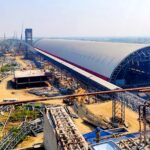

Large-scale manufacturing facilities operate in demanding environments, requiring structures that can withstand heavy loads, harsh weather conditions, and other challenges. Metalkarma’s spaceframe coverage sheds are engineered with durability and structural integrity in mind. Their robust construction and high-quality materials ensure long-term reliability, protecting valuable assets and operations from damage and disruption.

2. Customization and Flexibility:

Every manufacturing facility has unique requirements and spatial constraints. Metalkarma’s spaceframe coverage sheds offer customizable designs and configurations to accommodate diverse needs. Whether it’s size, layout, or additional features such as ventilation systems or loading docks, these sheds can be tailored to suit specific manufacturing processes and workflows. This flexibility allows large-scale manufacturers to optimize space utilization and operational efficiency.

3. Cost-Effectiveness and Return on Investment:

Investing in industrial coverage sheds is a significant decision for large-scale manufacturers. It’s essential to consider the total cost of ownership, including upfront costs, maintenance expenses, and long-term operational savings. Metalkarma’s spaceframe technology offers cost-effective solutions that minimize construction and maintenance costs while maximizing operational efficiency. The rapid deployment and scalability of these sheds ensure a quicker return on investment and long-term financial benefits for manufacturing facilities.

4. Environmental Sustainability:

Sustainability is increasingly important for modern manufacturing facilities. Metalkarma’s spaceframe coverage sheds are designed with eco-friendly materials and construction techniques that minimize environmental impact. These sheds can also be equipped with energy-efficient features such as insulation and natural lighting solutions, reducing energy consumption and carbon emissions. By choosing environmentally sustainable options, large-scale manufacturers can demonstrate their commitment to responsible business practices.

5. Compliance and Safety:

Ensuring compliance with safety regulations is paramount in manufacturing operations. Metalkarma’s spaceframe coverage sheds are engineered to meet industry standards for safety and structural integrity. From fire resistance to wind load capacity, these sheds provide a secure environment for workers and equipment. Additionally, customization options such as access control systems and safety features enhance workplace safety and regulatory compliance.

Conclusion:

Selecting the right industrial coverage shed is a critical decision for large-scale manufacturing facilities. By considering factors such as durability, customization, cost-effectiveness, environmental sustainability, and safety compliance, manufacturers can make informed choices that align with their operational needs and long-term objectives. Metalkarma’s spaceframe coverage sheds offer innovative solutions that address these factors, providing reliable, customizable, and cost-effective protection for large-scale manufacturing operations. With Metalkarma’s spaceframe technology, manufacturers can optimize their facilities for success in today’s competitive market landscape.