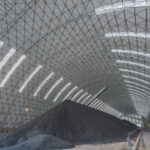

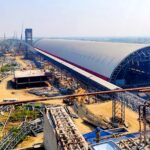

In industrial operations involving bulk materials like coal, ores, and aggregates, efficient material handling is crucial for productivity and environmental responsibility. Covered stacker reclaimer sheds, powered by Metalkarma’s spaceframes technologies, offer a comprehensive solution that not only optimizes material handling efficiency but also enhances pollution control. Let’s delve into the advantages of these innovative structures and their role in industrial sustainability.

1. Maximizing Material Handling Efficiency:

Covered stacker reclaimer sheds provide a controlled environment for material handling operations, optimizing efficiency and throughput. These structures house automated stacker reclaimers that can efficiently stack, store, and retrieve bulk materials with minimal manual intervention. Metalkarma’s spaceframes technologies enable the construction of large-span sheds that accommodate stacker reclaimer equipment, maximizing material handling capacity and streamlining operations.

2. Protection from Environmental Elements:

One of the key advantages of covered stacker reclaimer sheds is their ability to shield bulk materials from adverse environmental conditions. Traditional outdoor stacker reclaimer systems are susceptible to exposure to rain, wind, and sunlight, leading to material degradation and pollution risks. Covered sheds provide a protective barrier that minimizes exposure to the elements, preserving material quality and reducing pollution potential.

3. Minimizing Air and Water Pollution:

Covered stacker reclaimer sheds play a crucial role in pollution control by minimizing the release of dust, particulate matter, and other pollutants into the air and water. Enclosed material handling operations prevent airborne emissions and reduce the risk of contamination from runoff, safeguarding environmental quality and minimizing ecological impact. Metalkarma’s spaceframes technologies ensure the durability and resilience of covered sheds, even in harsh weather conditions.

4. Enhancing Worker Safety:

The enclosed environment of covered stacker reclaimer sheds enhances worker safety by minimizing exposure to hazardous conditions such as extreme weather and airborne pollutants. Personnel involved in material handling operations are protected from environmental hazards, reducing the risk of accidents and injuries. Additionally, the controlled environment of covered sheds ensures optimal working conditions for stacker reclaimer equipment, enhancing operational safety and reliability.

5. Supporting Sustainable Operations:

Investing in covered stacker reclaimer sheds demonstrates a commitment to sustainable industrial practices. By optimizing material handling efficiency and minimizing pollution risks, these structures contribute to resource conservation and environmental stewardship. Metalkarma’s spaceframes technologies enable the construction of eco-friendly infrastructure that aligns with industry goals of sustainability and responsible resource management.

Conclusion:

Covered stacker reclaimer sheds, powered by Metalkarma’s spaceframes technologies, offer a holistic solution for optimizing material handling efficiency and pollution control in industrial operations. By providing a controlled environment for material handling operations, minimizing pollution risks, enhancing worker safety, and supporting sustainable operations, these innovative structures play a crucial role in driving industrial efficiency and environmental responsibility. As industries continue to prioritize sustainability and operational excellence, covered stacker reclaimer sheds will remain indispensable assets in the quest for a cleaner, more efficient, and environmentally sustainable future.