Water pollution remains a pressing global concern, particularly in areas where industrial activities such as thermal power plants, cement factories, and mining operations are prevalent. These industries often utilize open storage facilities for materials like coal, iron ore, limestone, and other raw materials, leading to the potential contamination of nearby water bodies. Addressing this challenge requires innovative solutions that not only mitigate pollution but also ensure sustainable industrial practices. Enter Metalkarma Spaceframe Covering Sheds – a game-changing technology designed to revolutionize pollution control and environmental conservation in industrial settings.

Understanding the Impact of Industrial Activities on Water Pollution:

Industries such as thermal power plants, cement factories, and mining operations play a crucial role in global economic development. However, the open storage of raw materials like coal, iron ore, and limestone poses significant environmental risks, particularly in terms of water pollution. Rainwater and runoff can carry pollutants from these storage sites into nearby rivers, streams, and groundwater, contaminating water sources and harming aquatic ecosystems.

Challenges in Conventional Pollution Control Methods:

Conventional pollution control methods for industrial sites often involve the use of containment ponds, chemical treatments, and sedimentation basins. While these approaches may be effective to some extent, they often fall short in preventing pollution at its source. Moreover, the maintenance and operation of such infrastructure can be costly and resource-intensive, posing additional challenges for industries already grappling with regulatory compliance and sustainability concerns.

Metalkarma’s Innovative Solution:

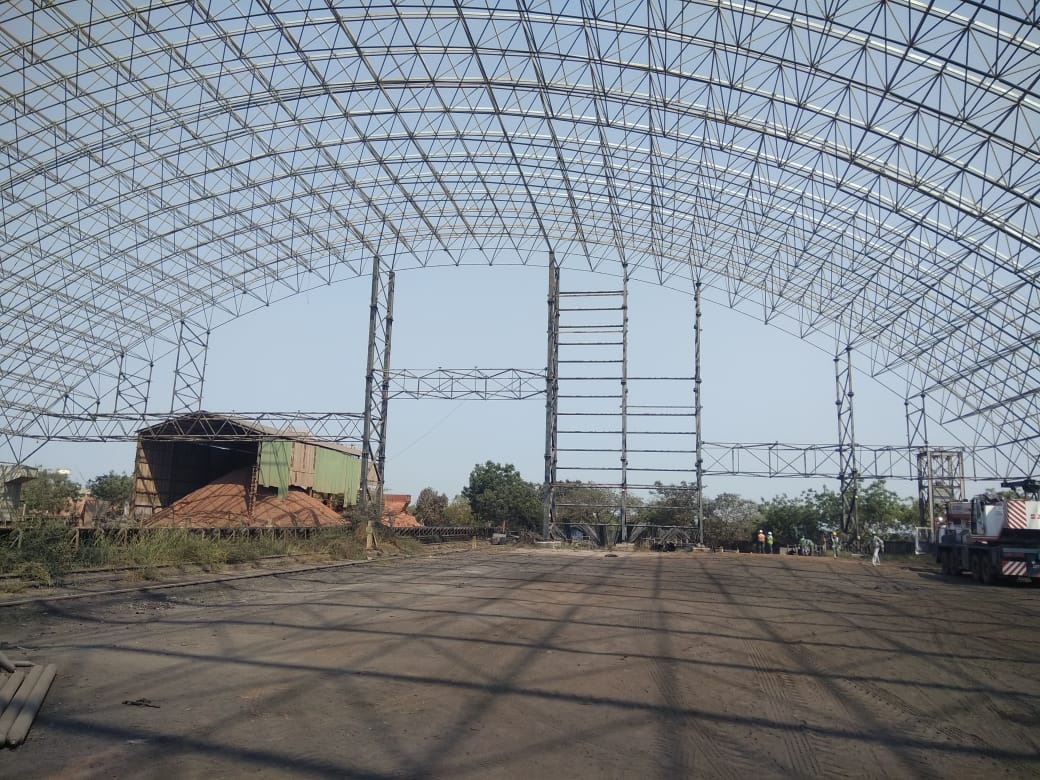

Metalkarma Spaceframe Covering Sheds offer a holistic and sustainable solution to the challenges of water pollution in industrial settings. These innovative structures, developed by Metalkarma Spaceframes Technologies, are designed to cover and protect open storage areas, mitigating the risk of contamination and preserving water quality. Here’s how they work:

- Customized Design: Metalkarma engineers tailor each covering shed to the specific requirements of the industrial site, taking into account factors such as layout, material type, and environmental conditions. The result is a bespoke solution that provides optimal coverage and protection against water pollution.

- Advanced Materials: The spaceframe covering sheds are constructed using high-quality materials that offer durability, weather resistance, and structural integrity. This ensures long-term performance and reliability, even in harsh industrial environments.

- Integrated Drainage Systems: To prevent the buildup of rainwater and runoff within the covered storage areas, Metalkarma’s sheds feature integrated drainage systems. These systems efficiently channel water away from the storage site, reducing the risk of contamination and minimizing the need for additional pollution control measures.

- Sustainable Operations: In line with Metalkarma’s commitment to sustainability, the covering sheds are designed to optimize energy efficiency and minimize environmental impact. Where feasible, renewable energy sources such as solar power are integrated into the sheds’ infrastructure, further reducing their carbon footprint.

Conclusion:

Water pollution from industrial activities poses a significant threat to the environment and public health. However, with innovative solutions like Metalkarma’s Spaceframe Covering Sheds, industries can effectively mitigate pollution and uphold their commitment to environmental stewardship. By embracing cutting-edge technology and sustainable practices, we can create a future where industrial development coexists harmoniously with environmental conservation. Together, let us work towards a cleaner, healthier planet for generations to come.